PTO vs Belt Driven Water Pump for Tiller – Which Should You Choose?

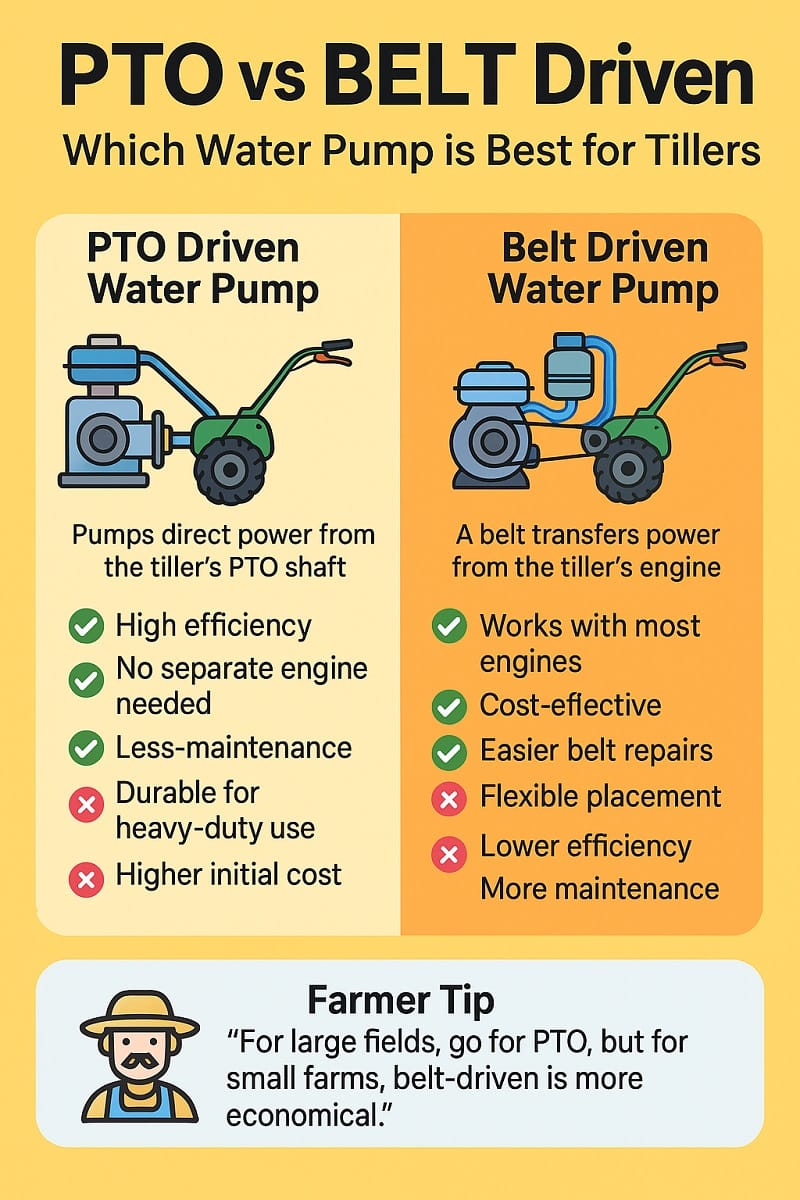

In Indian agriculture, tillers and mini-tractors are increasingly used not just for tilling, but also for multiple farm operations such as irrigation. One popular attachment is the water pump, which can be driven in two main ways: via the PTO (Power Take-Off) shaft or a belt-driven system. But which one is better for your needs? Let’s break it down.

🔍 What is a PTO PTO-driven water Pump?

A PTO-driven water pump connects directly to the power take-off shaft of your tiller or tractor. The PTO transfers the engine’s rotational power directly to the pump, eliminating the need for an external power take-off (PTO).

✅ Advantages

- Higher power transfer efficiency (less energy loss)

- No need for a separate engine or fuel source

- Fewer moving parts compared to belt systems

- More durable for long-term use

⚠️ Disadvantages

- Requires a compatible PTO shaft size and speed

- Direct load on the tiller engine – may affect performance during simultaneous tasks

- Less flexibility in pump positioning

🔍 What is a Belt-Driven Water Pump?

A belt-driven water pump uses a pulley and belt system connected to the tiller engine or an additional small engine. The belt transfers power to the pump shaft.

✅ Advantages

- More flexibility in placement and alignment

- Belts can act as a “shock absorber,” reducing strain on the engine

- Easier and cheaper to repair (belt replacement is simple)

- Can work with engines that do not have a PTO

⚠️ Disadvantages

- Power loss due to belt slippage

- Belts wear out over time, requiring regular replacement

- Less efficient for high-pressure, high-volume pumping

📊 PTO vs Belt Driven Water Pump – Comparison Table

| Feature | PTO Driven | Belt Driven |

|---|---|---|

| Efficiency | High (90%+) | Moderate (75–85%) |

| Maintenance | Low (mainly lubrication) | Moderate (belt replacement) |

| Cost | Higher initial investment | Lower cost, affordable for small farmers |

| Durability | More durable for heavy-duty work | Good for light to medium work |

| Setup | Requires PTO-equipped tiller | Can be adapted to most engines |

💡 Which One Should You Choose?

- Choose PTO-driven if you already have a PTO-equipped tiller, need high efficiency, and want long-term durability for large-scale irrigation.

- Choose belt-driven if your tiller lacks a PTO, you want lower initial costs, or you need flexibility in pump placement.

📍 Best Use Cases in Indian Farming

In India, PTO-driven pumps are preferred by farmers with large plots and heavy irrigation needs (sugarcane, paddy, banana plantations), while belt-driven pumps are more common among small farmers with seasonal or limited irrigation requirements.

🧑🌾 Farmer Tip

“I started with a belt-driven pump for my 2-acre vegetable farm because it was cheap and easy to set up. Later, when I upgraded to a PTO tiller, I switched to a PTO pump for better efficiency.”

– Ramesh Pawar, Farmer from Kolhapur, Maharashtra

📦 Final Verdict

Both PTO and belt-driven water pumps have their place in Indian agriculture. The right choice depends on your budget, tiller compatibility, and irrigation needs. Investing in the right pump can save fuel, reduce maintenance, and improve irrigation efficiency.